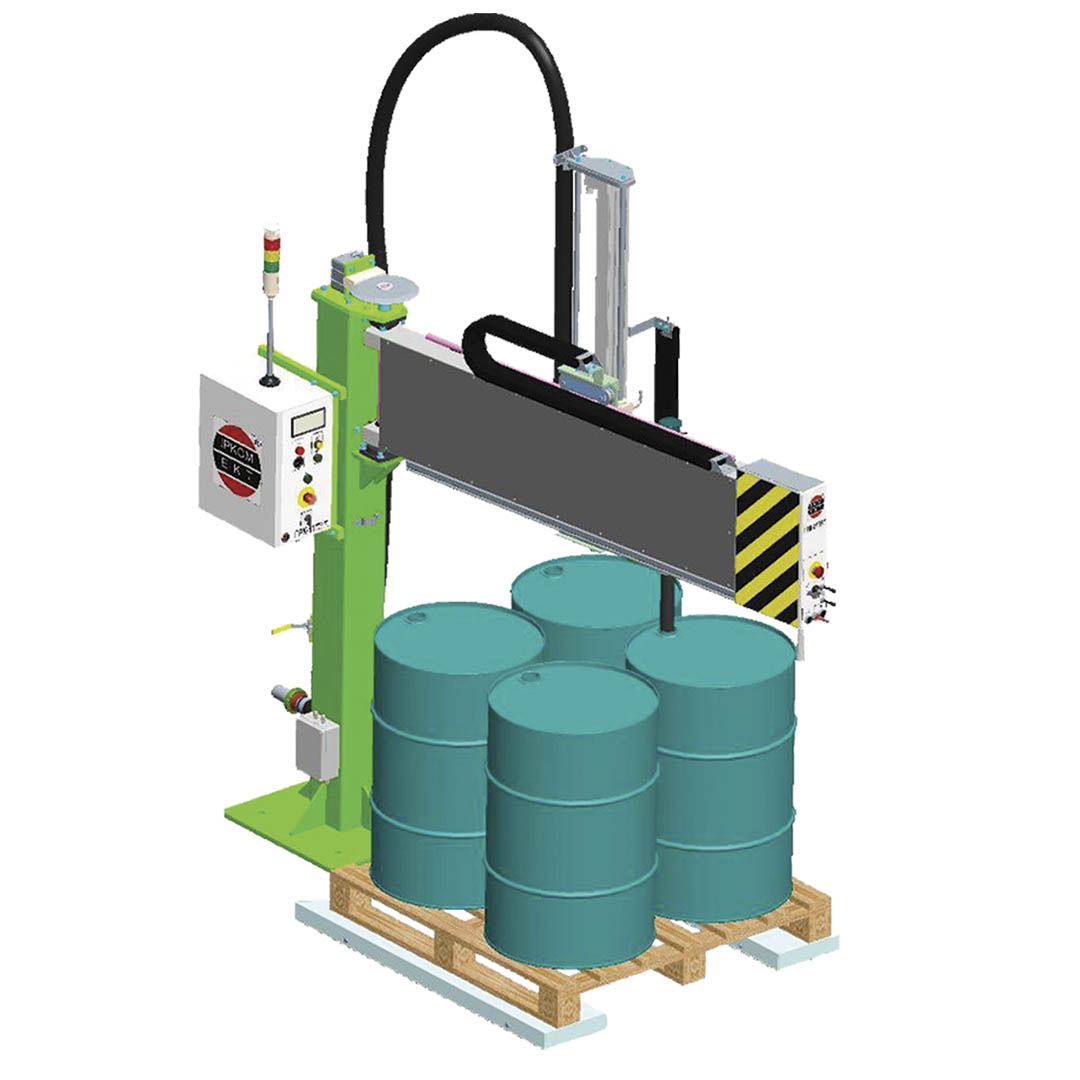

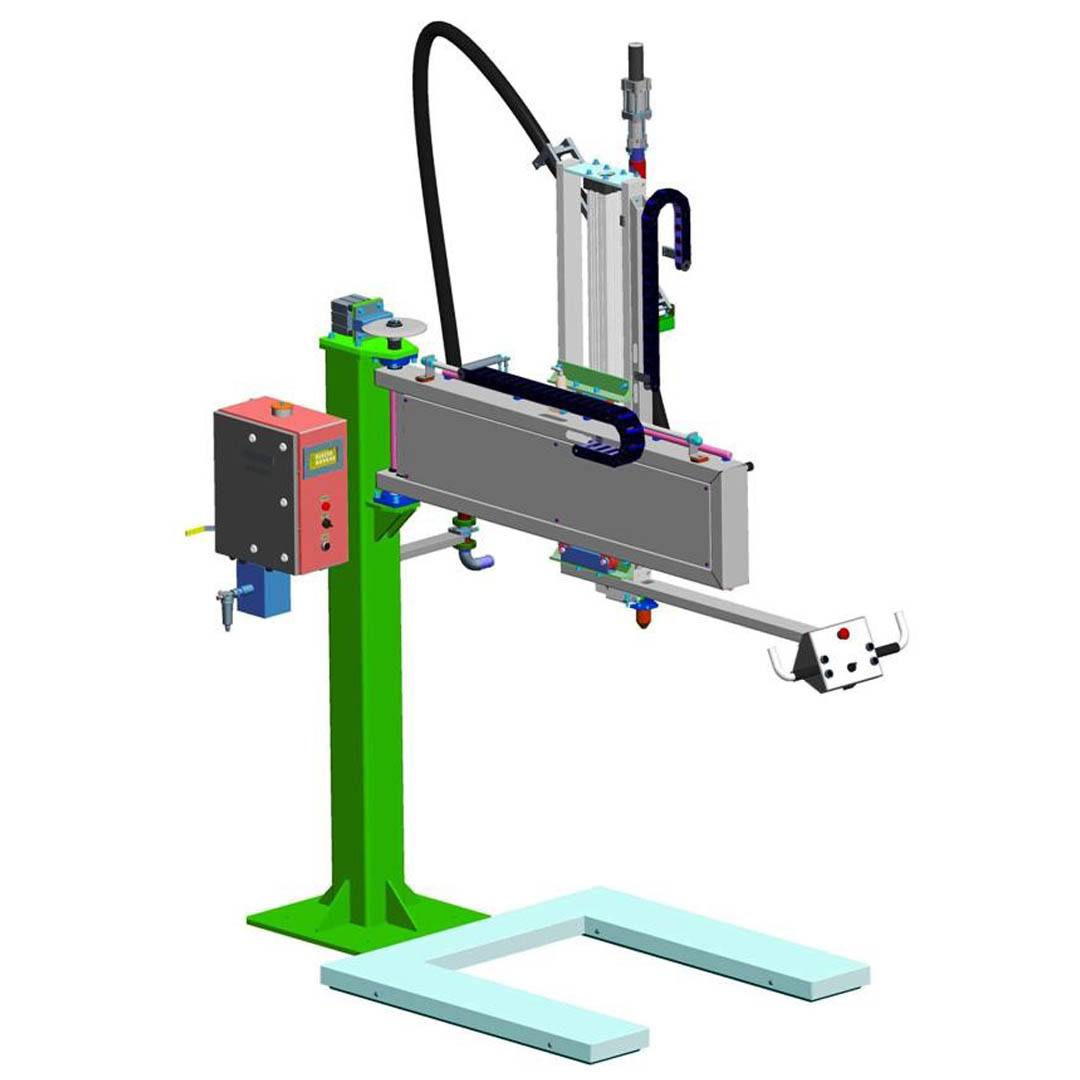

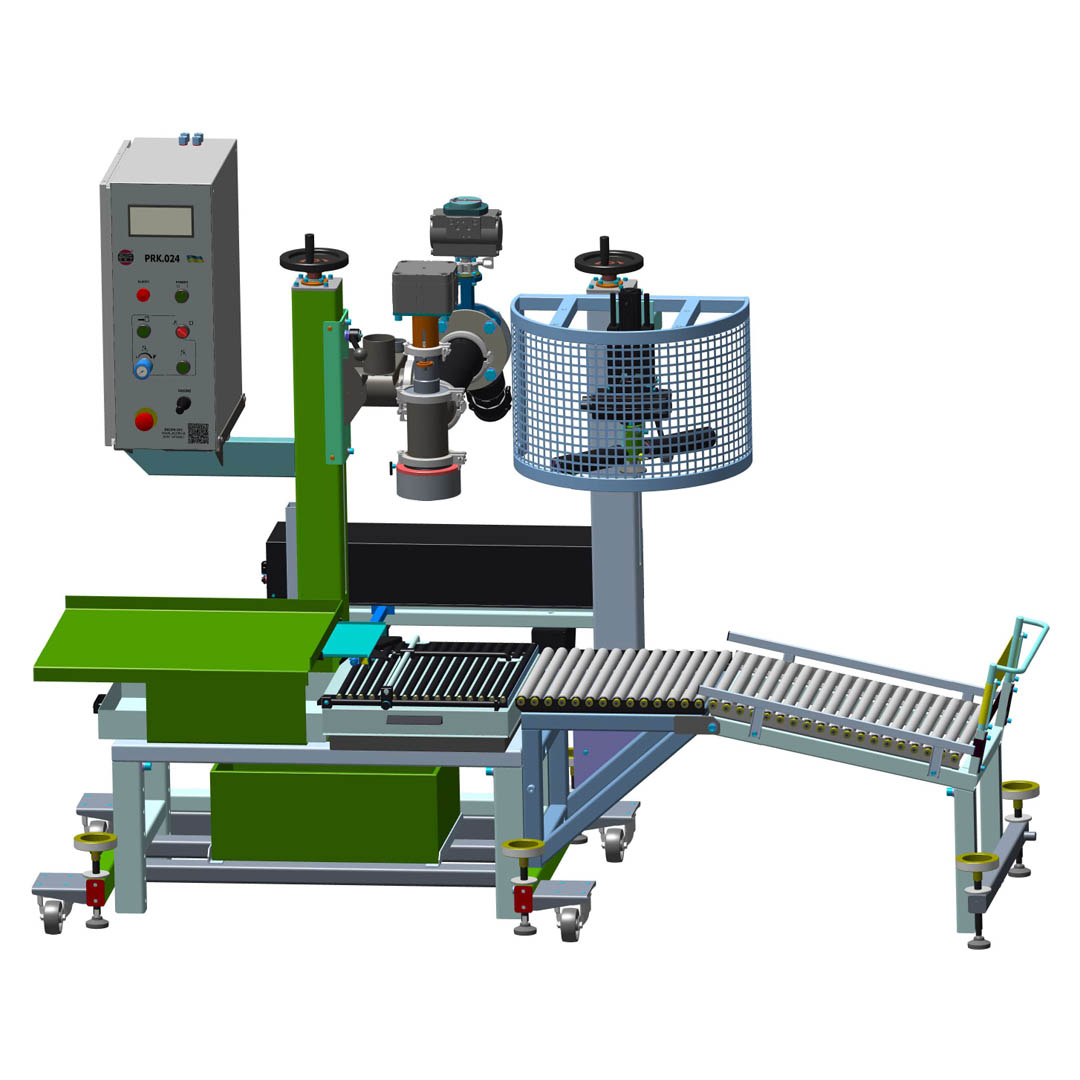

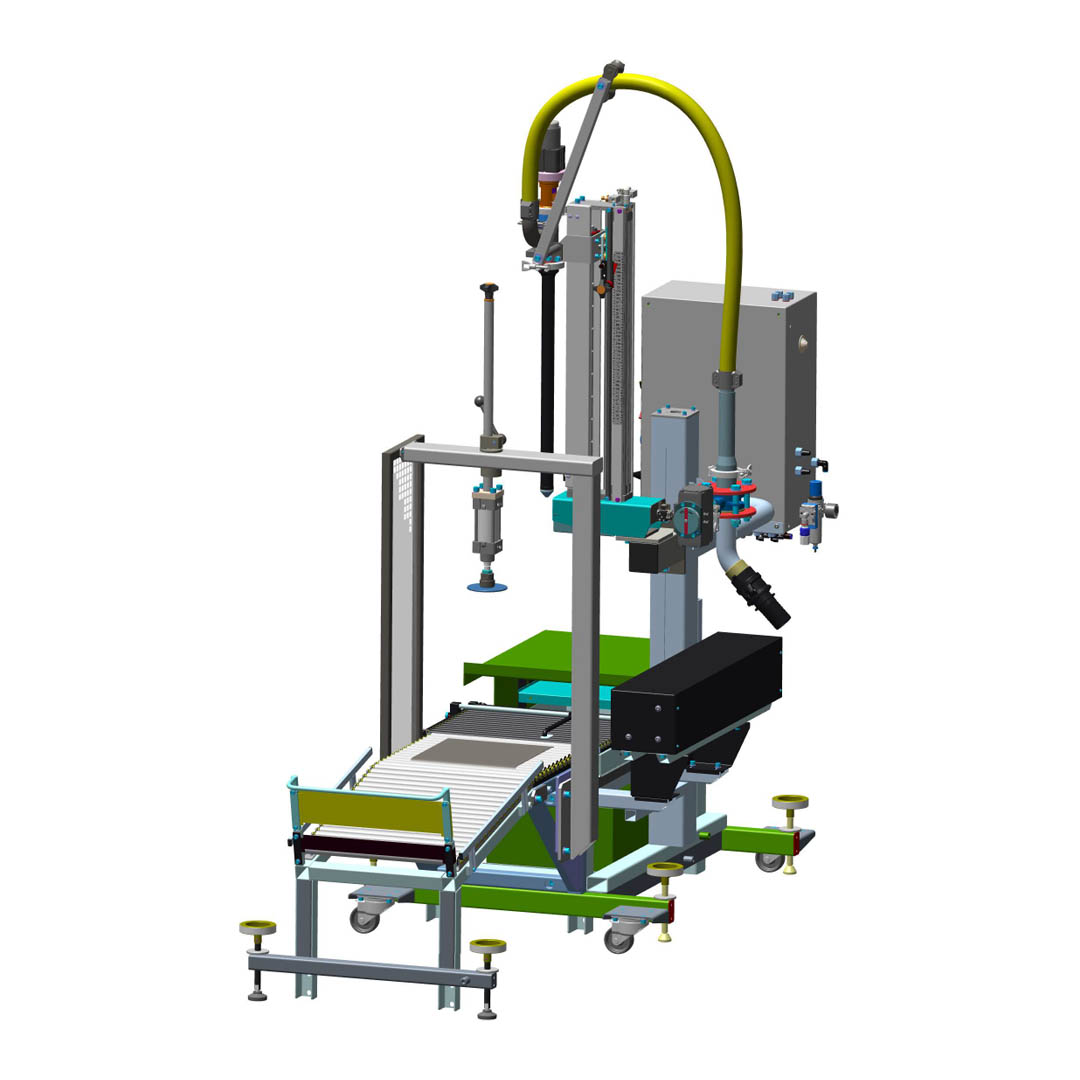

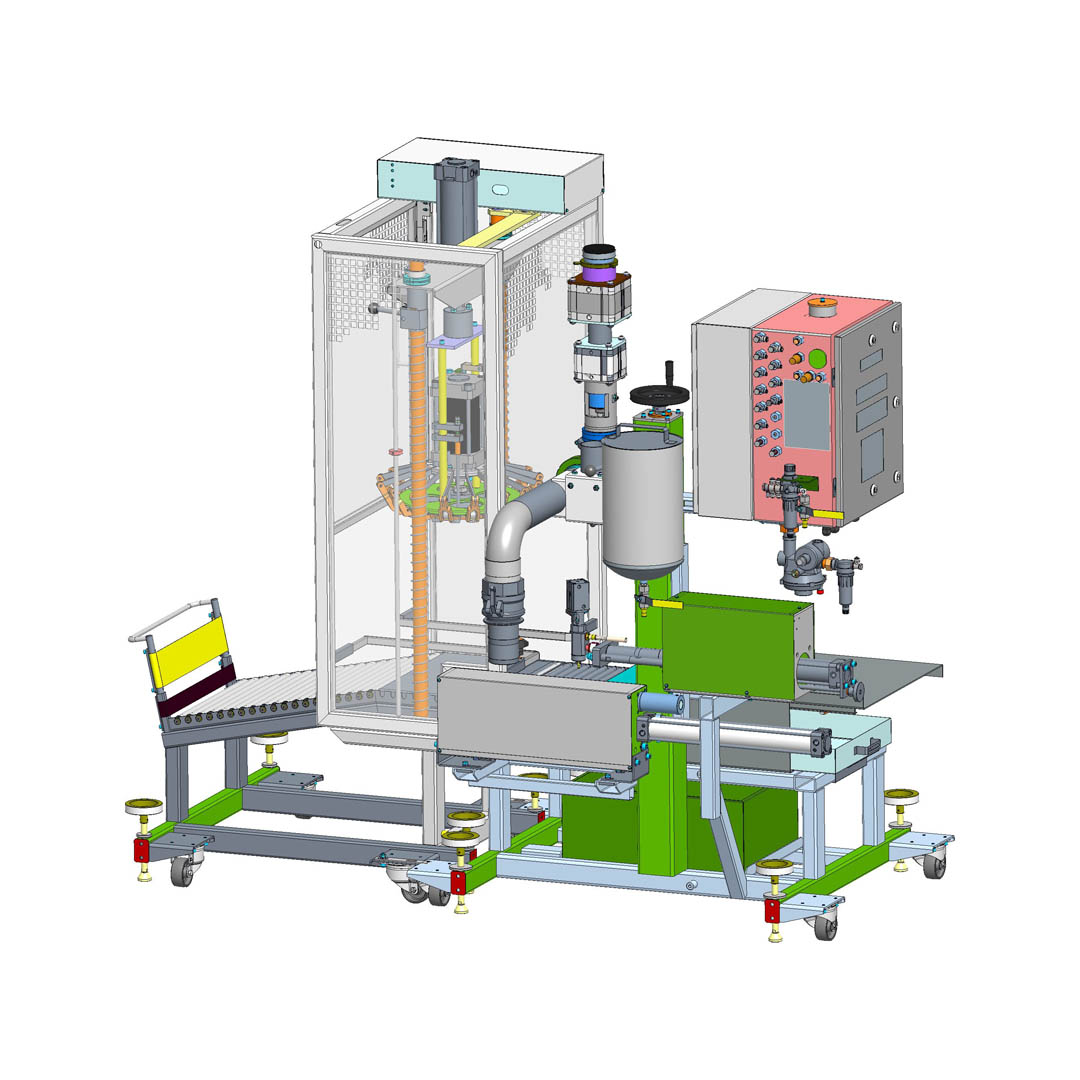

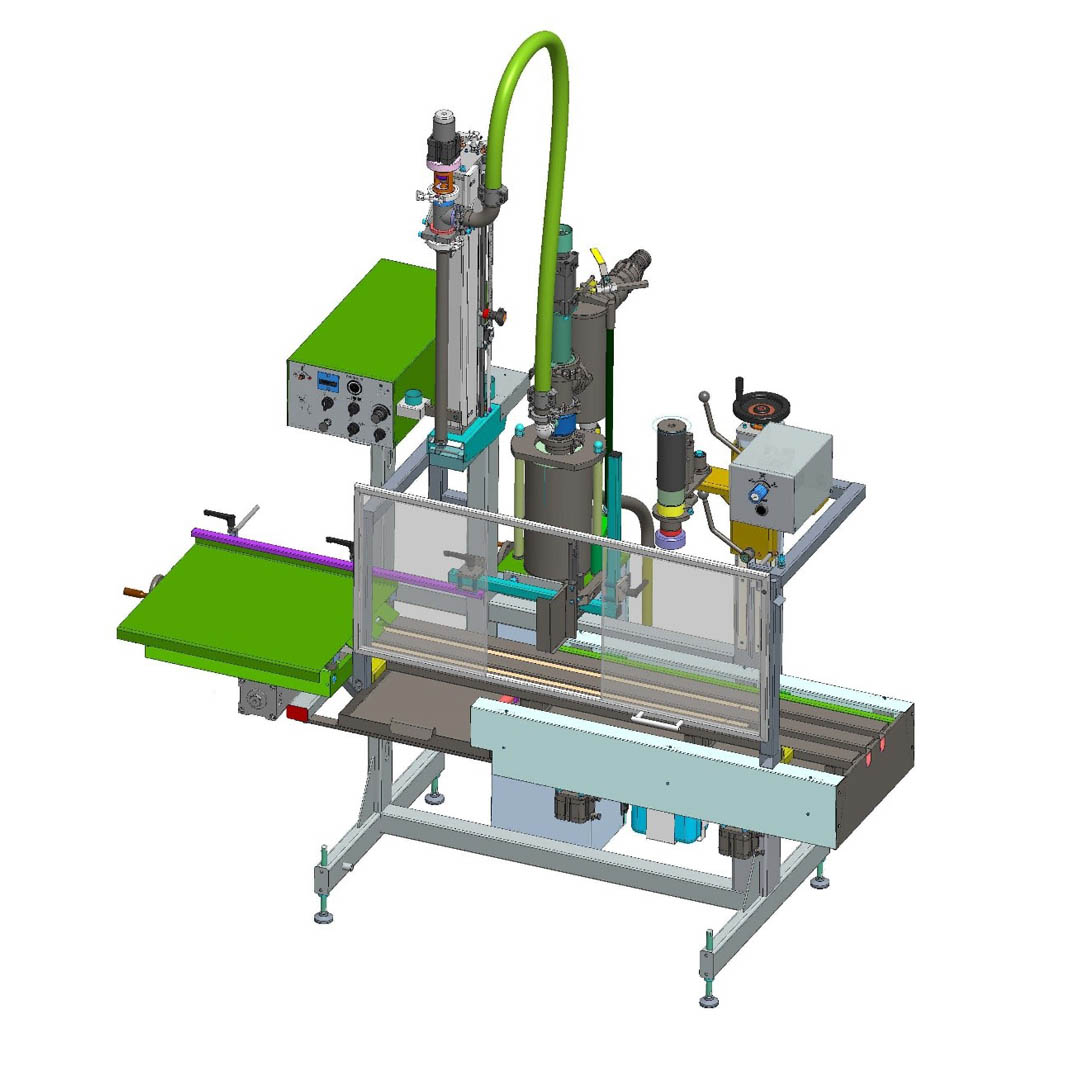

PRK.11-02 Semi-automatic gravimetric filling unit for metal drums in groups of four drums

on order

Intended for gravimetric filling of organic liquids into 216.5 L metal drums arranged into groups of 4 drums placed on pallets.

The filling process is as follows:

- the filler valve is manually installed next to the container filler neck by moving the slewing boom and the travelling carriage with the filler valve;

- the boom and carriage are locked in place by a brake upon a control panel command;

- product filling cycle starts upon a control panel command;

- product filling cycle ends automatically after the preset filling weight is reached;

- the process is repeated for all container units on the pallet.

The control system based on a microcontroller (secondary instrument for load cell signal transformation) allows:

- dynamic adjustment of the tolerance, i. e. taking into account physical and chemical properties of the liquids being filled;

- registering the number of containers being filled;

- displaying the filled product weight;

- storing of up to 20 filling programs.

| Purpose | Filling of anti-freeze solution; Filling of white spirit; Filling of solvent; Filling of engine oil |

| Container | into metal drums |

| Dose volume | 5–20 L; above 20 L |

| Filling method | below bunghole filling; below level filling |

| 1.Filling principle | gravimetric |

| 2.Weight of 1 dose in a group | minimum, kg10.0 |

| Weight of 1 dose in a group | maximum, kg600.0 |

| 3.Dosing tolerance for 5–300 kg dose | ≤±50 g |

| for 300–1,000 kg dose | ≤±75 g |

| for 1,000–1,900 kg dose | ≤±100 g |

| 4.Compressed air supply pressure, MPa | 0.4–0.6 |

| 5.Compressed air flow, m³/h, max. | 3.0 |

| 6.Power input, kW, max. | 0.2 |

| 7.Dimensions, mm | 1,500х1,300х2,000 |

| 8.Weight, kg | 800 |

| 9.Capacity*, kg/h | 5,000 to 12,000 |

| 10.Version | standard or explosion-proof |

Related products

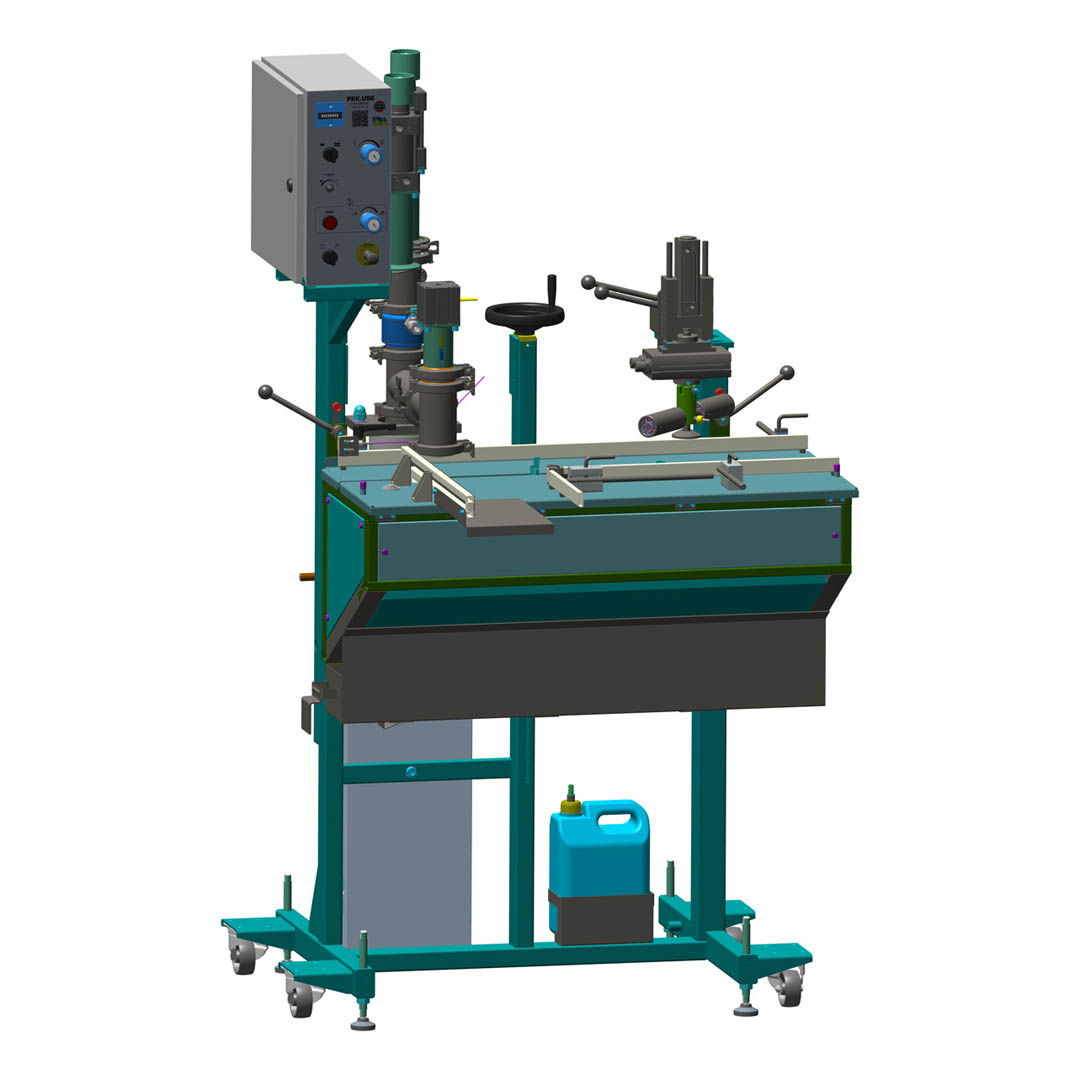

- Purpose Filling of water-based paints

- Purpose Filling of water-based putties

- Container into cylindrical plastic buckets

- Container into oval plastic buckets

- Purpose Filling of water-based paints

- Purpose Filling of organic solvent paints

- Purpose Filling of water-based putties

- Purpose Filling of organic solvent putties

- Purpose Filling of water-based paints

- Purpose Filling of water-based putties

- Container into cylindrical plastic buckets

- Container into oval plastic buckets

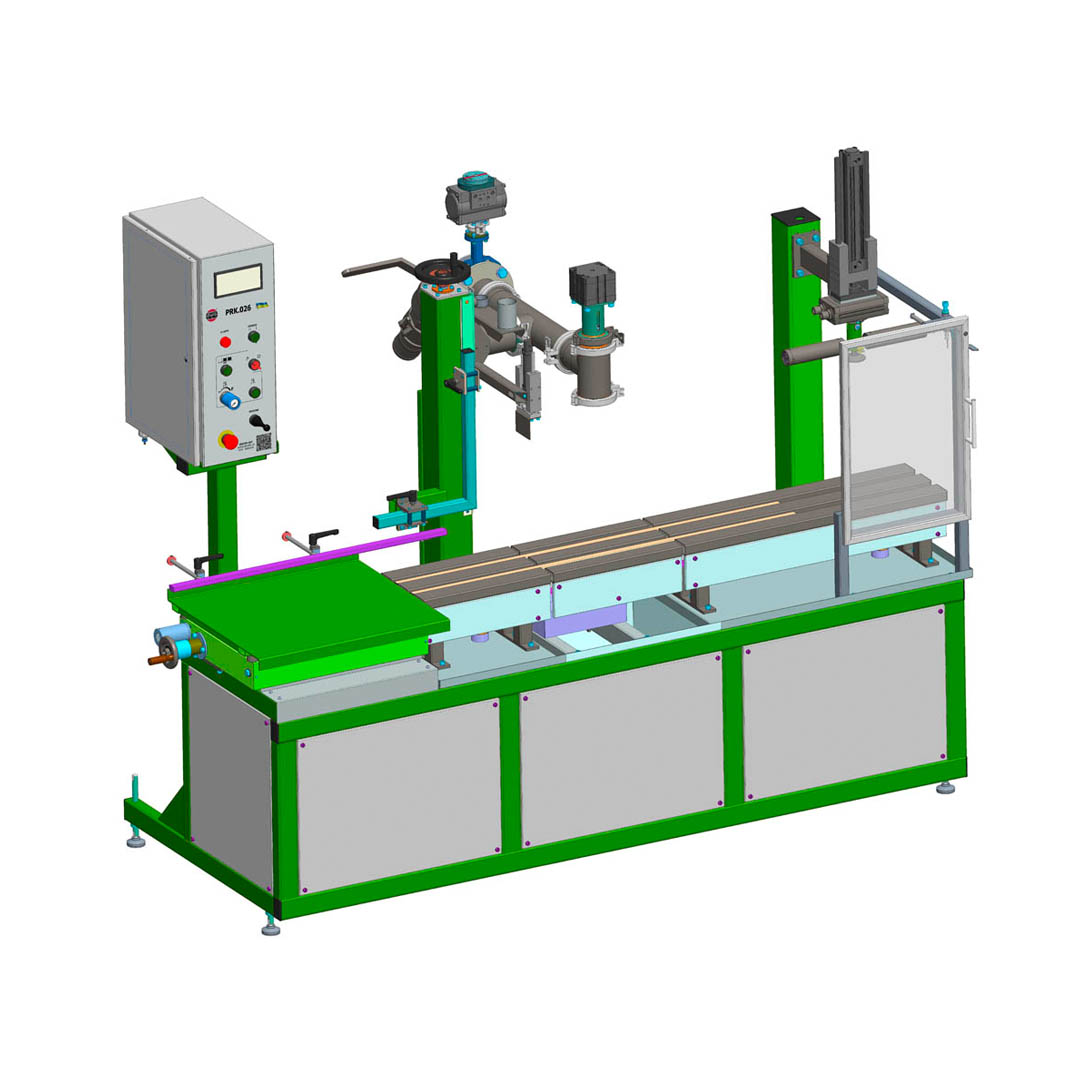

- Purpose Filling of white spirit

- Purpose Filling of solvent

- Purpose Filling of solvents 646, 647, 650

- Purpose Filling of wiper fluid

- Purpose Filling of organic solvent paints

- Purpose Filling of organic solvent putties

- Purpose Filling of bitumen mastics

- Container into lug lid metal buckets

- Purpose Filling or primers

- Container into plastic jerry cans