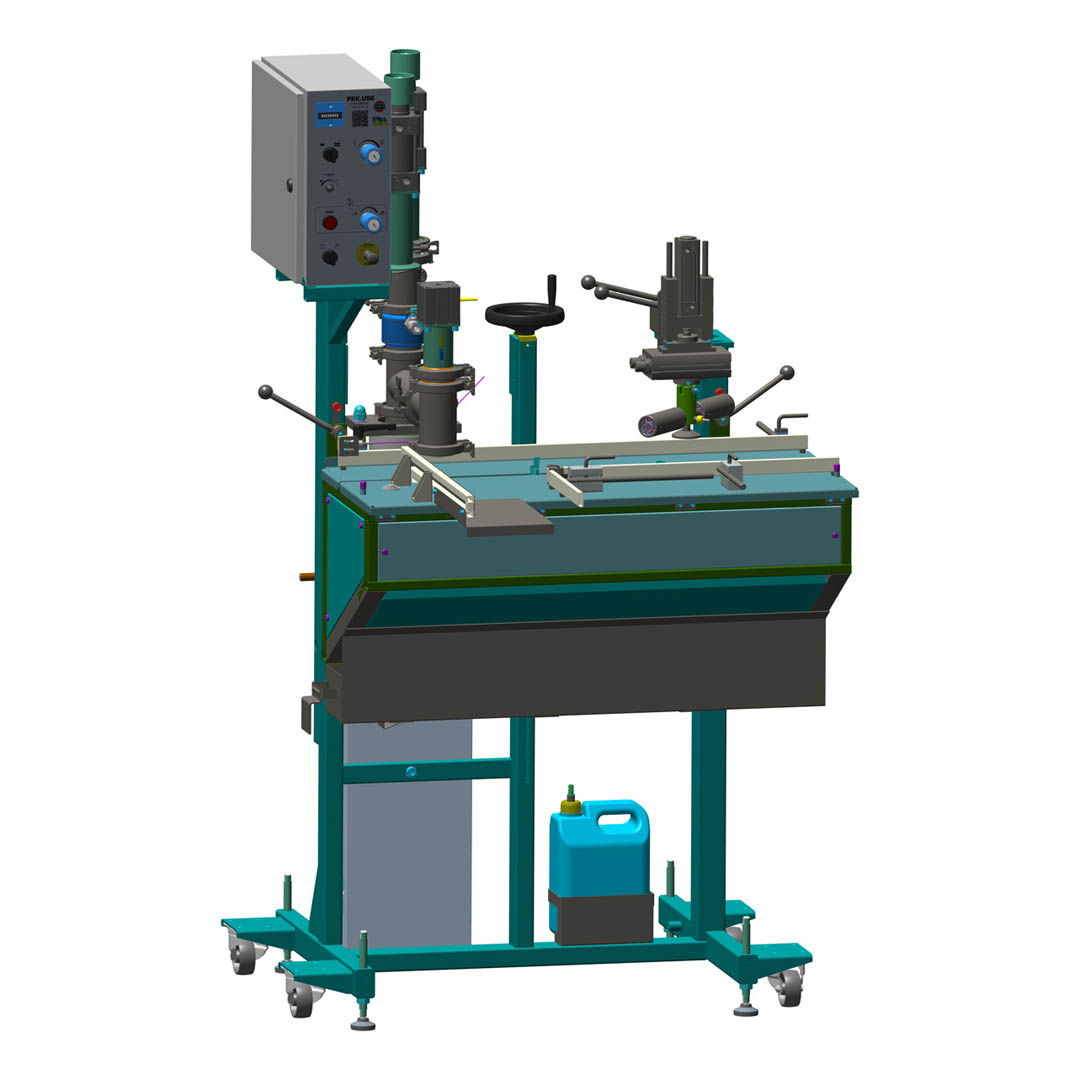

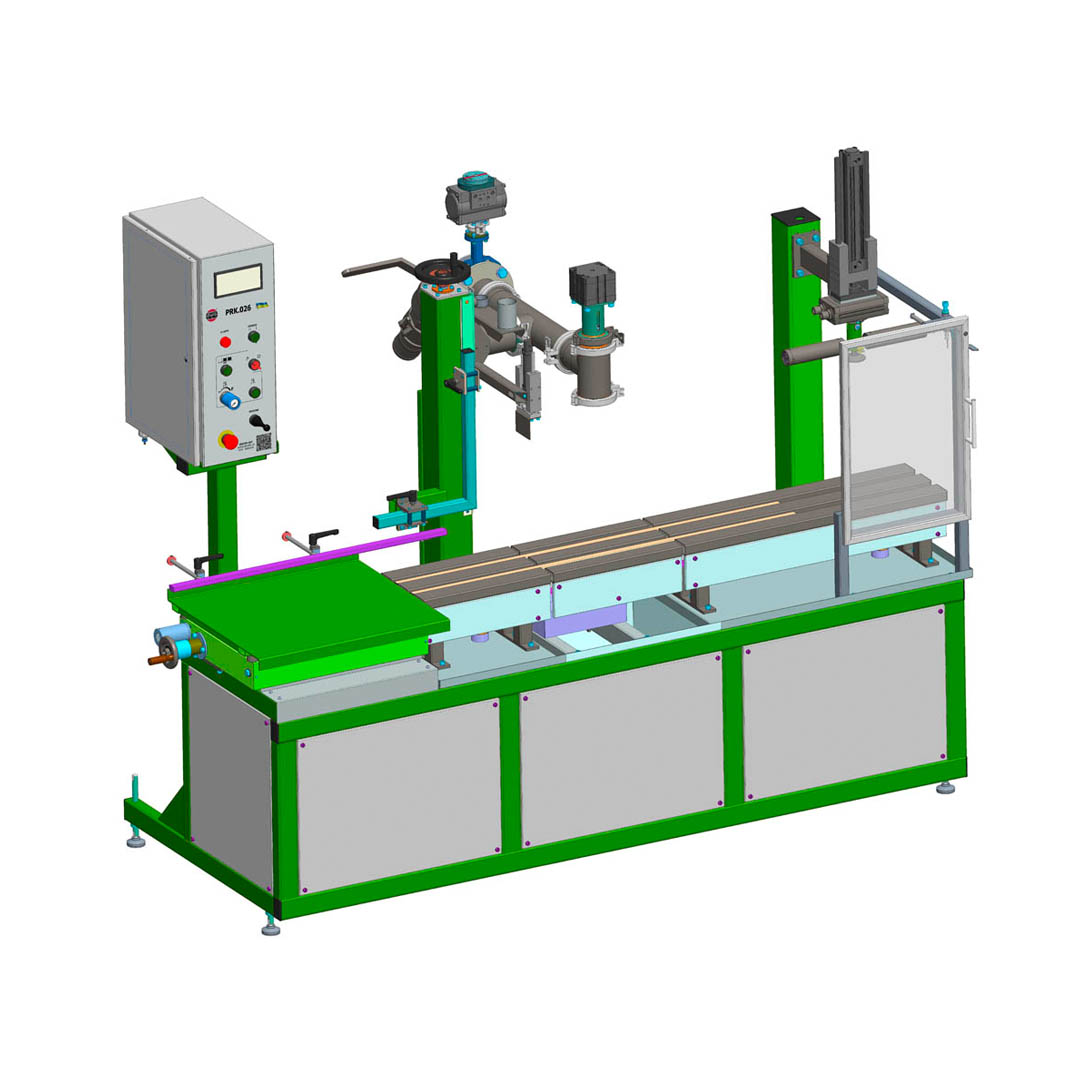

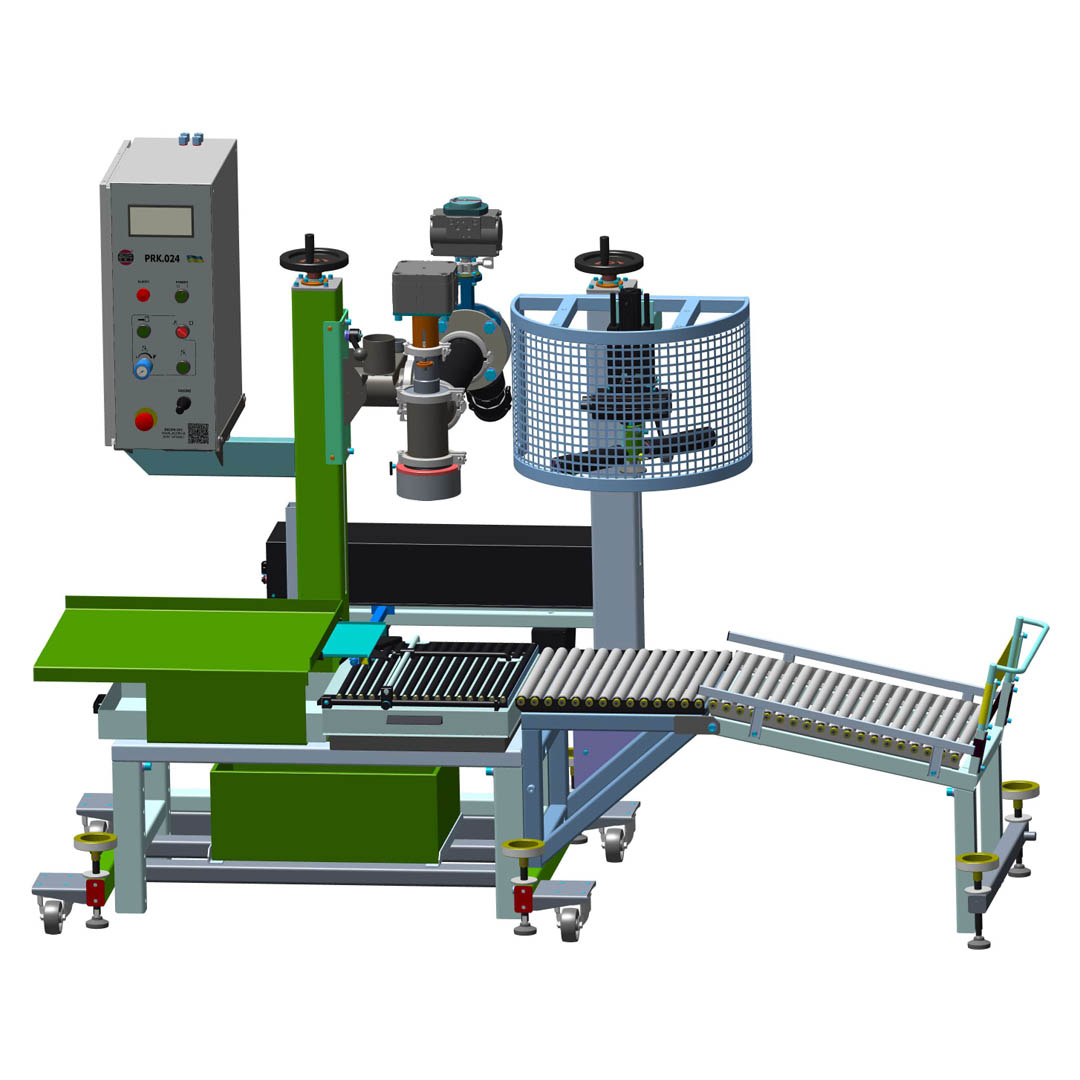

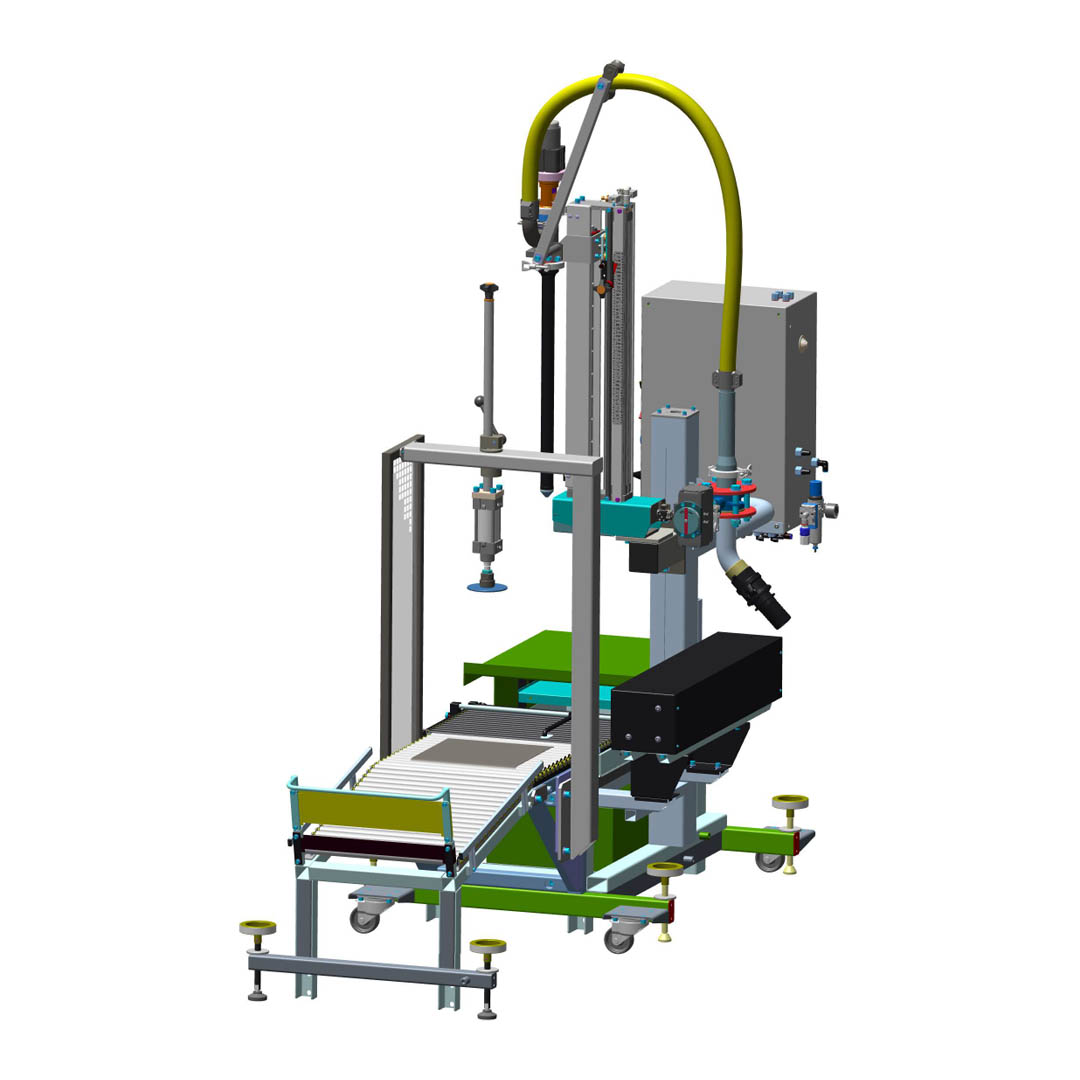

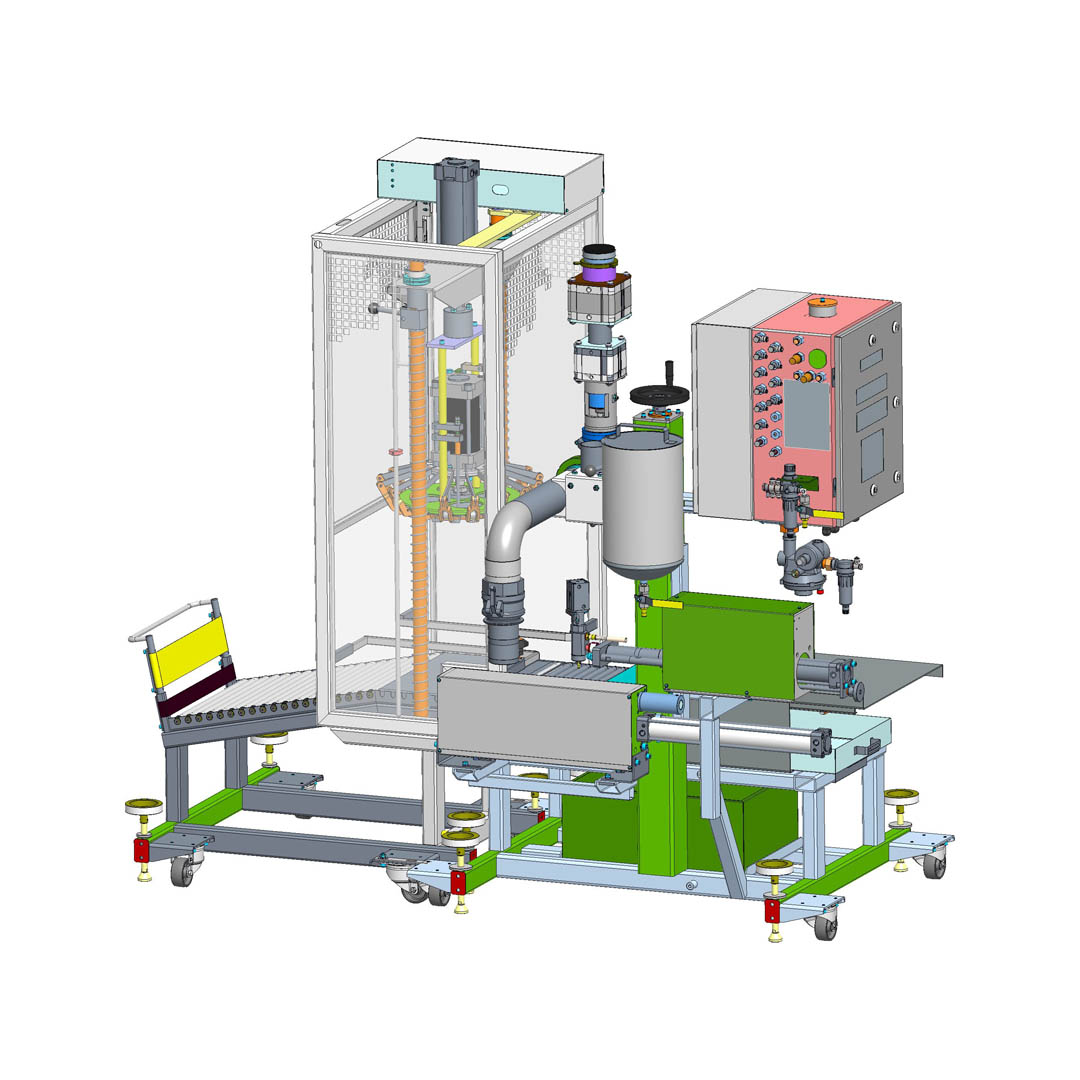

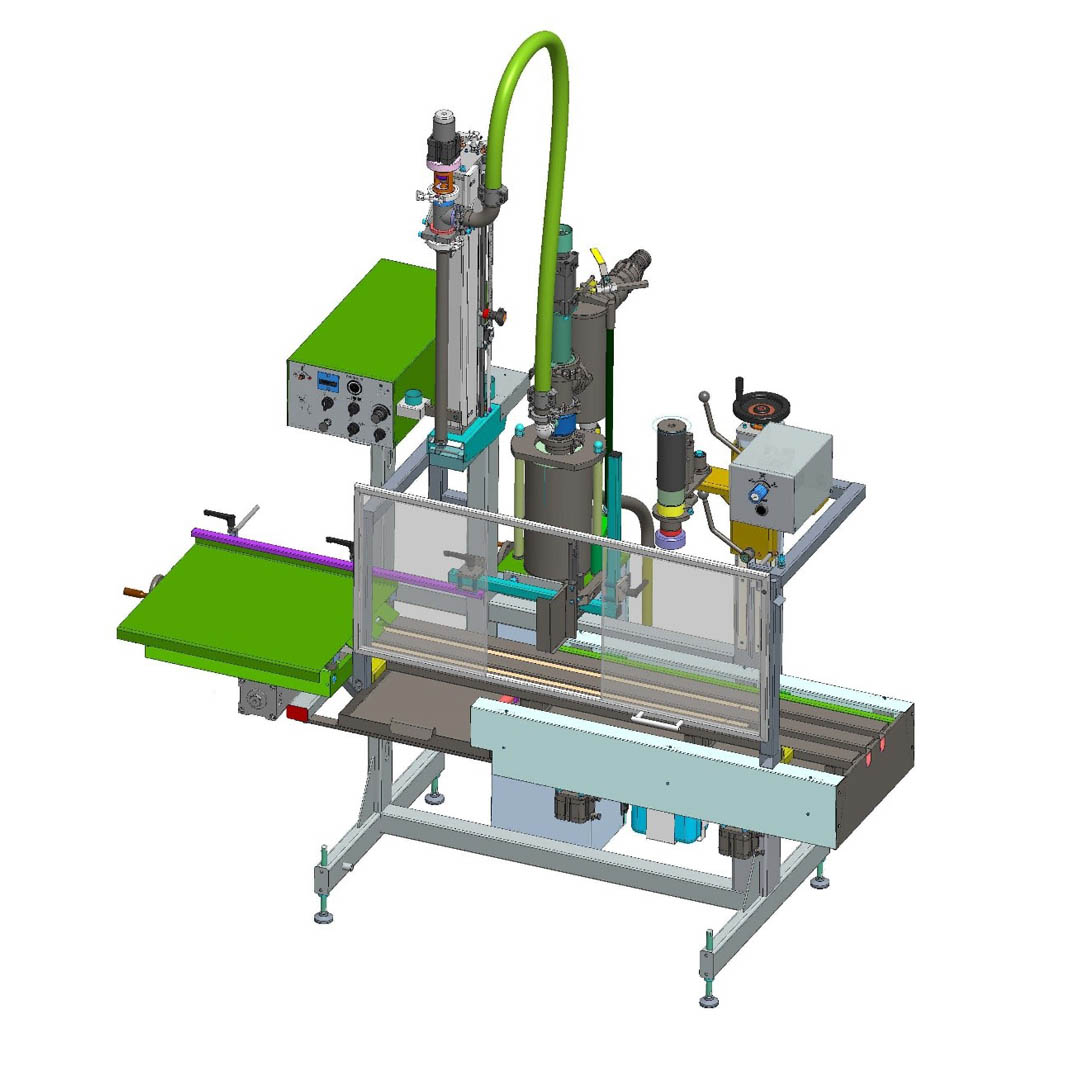

PRK.11 Semi-automatic gravimetric filling unit for industrial packaging

on order

The semi-automatic unit is intended for gravimetric filling of organic liquids into single metal drums.

Components:

- Platform scale with a roller table.

- Product flow control valve.

- Filler valve with a drop nozzle.

- Programmable controller system.

- Approach roller table, L=1.2 m.

- Run-out roller table, L=1.2 m.

- Explosion-proof version is available.

Semi-automatic unit features:

- container filling start – by pressing the button (manually);

- container filling stop – automatic, by setting up the filling weight;

- dosing start and stop – light and sound alarm;

- container filling provided the nozzle gets into the container filler neck.

- dynamic adjustment of the tolerance is provided, i. e. physical and chemical properties of the liquids being filled are taken into account;

- filling time is optimized during gravity filling (it changes due to the filled liquid level drop);

- the number of containers being filled is displayed;

- filled product weight is shown;

| Purpose | Filling of anti-freeze solution; Filling of white spirit; Filling of solvent; Filling of engine oil |

| Container | into metal drums |

| Dose volume | above 20 L |

| Filling method | below bunghole filling; below level filling |

| 1.Filling method | gravimetric (net weight) |

| 2. Capacity, kg/h | 5,000–12,000 |

| 3.Container feeding method | single drums |

| 4.Dose weight, minimum (net), kg | 100.0 |

| 5. Maximum measured weight, kg, max. | as per order |

| 6.Maximum dose value, kg | 300 |

| 7.Dosing tolerance, % | ±0.5-1 |

| 8.Platform scale dimensions, length x width, mm | 650 х 650 |

| 9.Minimum diameter of container neck, mm | 40 |

| 10.Compressed air supply pressure, kg/cm2 | 4-7 |

| 11.Compressed air flow, m³/h, max. | 2.0 |

| 12.Power supply | 220 VAC, 50 Hz |

| 13.Power input, kW, max. | 0.1 |

| 14. Load cells | FLINTEC |

| 15. Version | standard or explosion-proof |

Related products

- Purpose Filling of water-based paints

- Purpose Filling of water-based putties

- Container into cylindrical plastic buckets

- Container into oval plastic buckets

- Purpose Filling of water-based paints

- Purpose Filling of organic solvent paints

- Purpose Filling of water-based putties

- Purpose Filling of organic solvent putties

- Purpose Filling of water-based paints

- Purpose Filling of water-based putties

- Container into cylindrical plastic buckets

- Container into oval plastic buckets

- Purpose Filling of white spirit

- Purpose Filling of solvent

- Purpose Filling of solvents 646, 647, 650

- Purpose Filling of wiper fluid

- Purpose Filling of organic solvent paints

- Purpose Filling of organic solvent putties

- Purpose Filling of bitumen mastics

- Container into lug lid metal buckets

- Purpose Filling or primers

- Container into plastic jerry cans