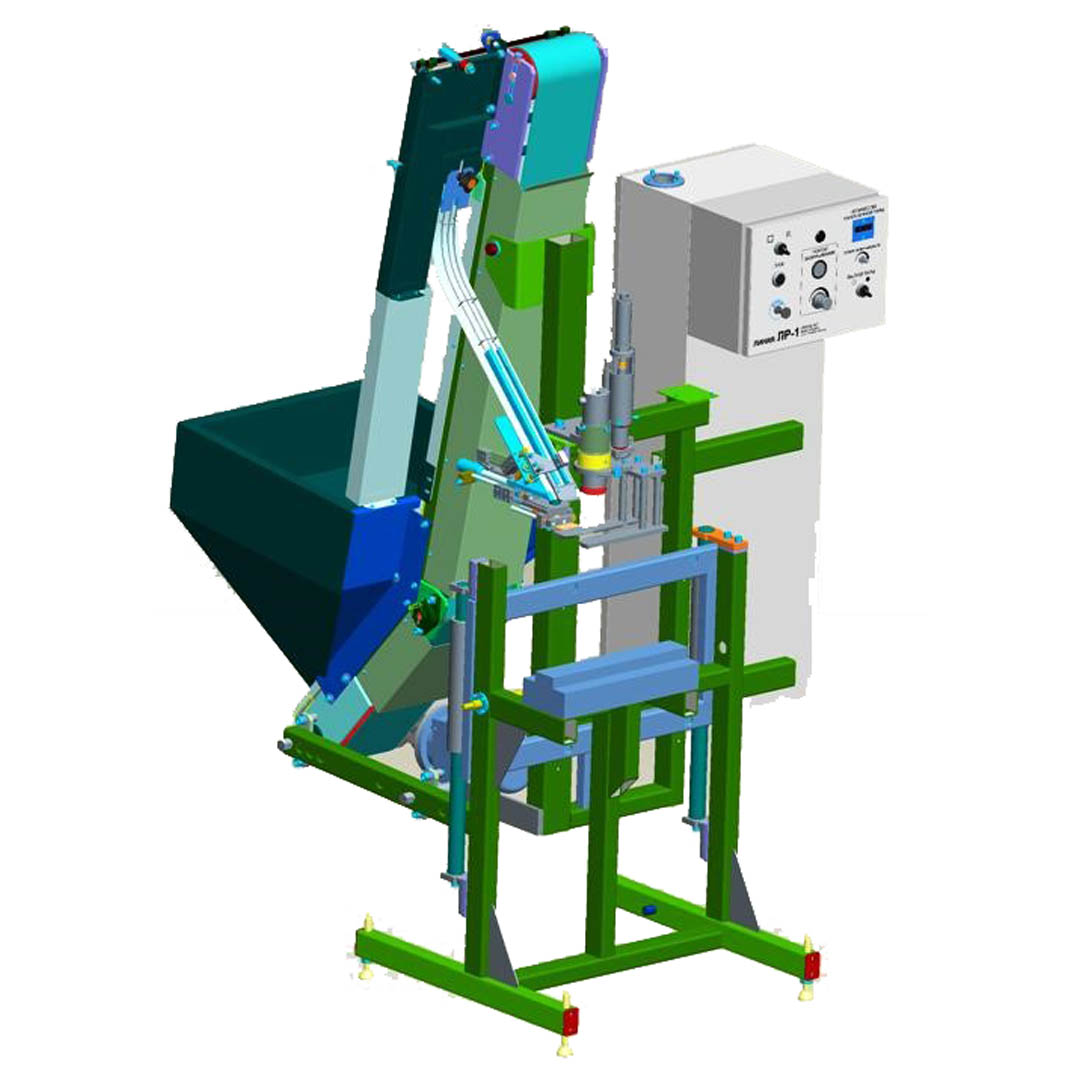

FNS.01 Filtration and pumping unit with a pulsation dampener

on order

Intended for product feeding from the container to the filling unit.

Filtration is carried out using replaceable filter bags with various selectivity values (50 to 1,000 μm).

Filtration is not used for filling or pumping of filled products: in this case, the filter bag along with the basket and the ballast tank is removed from the filter bottle. The pumping unit is used for pumping products with a solid inclusion size up to 6 mm.

The unit can be complete with Sandpiper diaphragm pumps with 1" to 3ʺ connection, with diaphragms and ball valve of Teflon™, (which makes it compatible with organic products) or Santoprene™ (for use with water-based products).

| 1. Maximum output (water) | depends on the installed pump type |

| - 1" pump, L/min | 170 |

| - 1.5" pump, L/min | 401 |

| - 2" pump, L/min | 567 |

| 2. Compressed air flow (when pumping) | depends on the installed pump type |

| - 1" pump, m3/h, max. | 68 |

| - 1,5\” pump, m3/h, max. | 85 |

| - 2\” pump, m3/h, max. | 170 |

| 3. Operating pressure, bar, max. | 6 |

Related products

- Purpose Filling of water-based paints

- Purpose Filling of water-based putties

- Container into cylindrical plastic buckets

- Container into oval plastic buckets

- Container into lug lid metal buckets

- Container into Bericap tin containers

- Container into flat lid tin cans

- Container into plastic jerry cans

- Container into PET bottles

- Container into glass bottles